Your basket is currently empty!

What is orthodox tea?

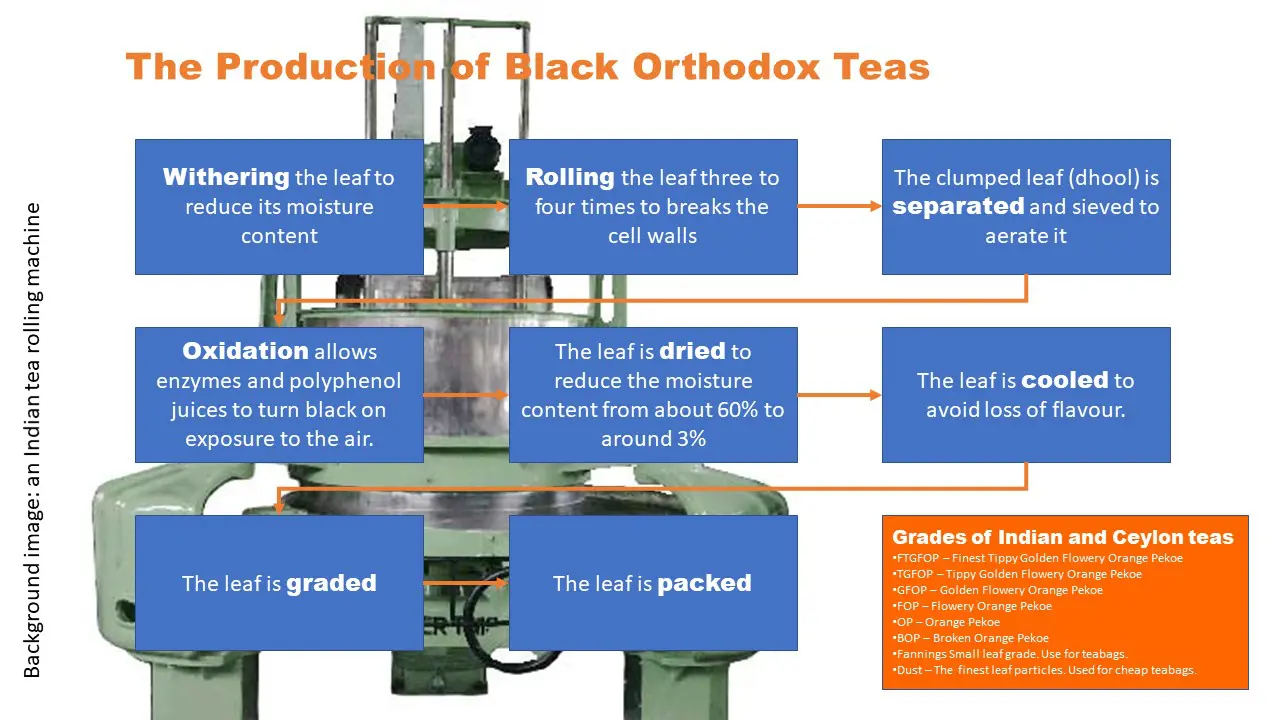

Orthodox tea is traditionally made whole leaf tea graded by size. It uses a time-consuming batch process requiring many skills which aims to make the most of the flavour components of the leaf and coax out the subtle nuances of taste. The benefits of orthodox tea are therefore more complexity and balanced flavours than CTC (Cut Tear Curl) tea. It is however a less efficient process than the CTC process. So what is orthodox tea? It uses the following process:

- Withering the leaf to reduce its moisture content. Unlike the CTC process the leaf is not cut into pieces. Withering takes twelve to sixteen hours. In addition, if it has been raining the leaf can be very wet indeed! Orthodox tea generally requires a hard wither as a greater proportion of the moisture content of the leaf needs to be removed. CTC teas generally have a soft wither, removing less of the moisture content.

- Rolling the leaf three to four times to breaks the cell walls and bruises the leaf, releasing juices without tearing the leaf. Originally done by hand, this process has used mechanical brass rollers over raised surfaces since they were first invented in 1872 by William Jackson in Assam. Rotorvane machines which have a drum with a central auger which pulls the leaf through, crushing the leaf and generating heat is only used for CTC teas as these machines will break the leaf.

- For the production of black teas, oxidation allows enzymes and polyphenol juices to turn black on exposure to the air. The clumped leaf (dhool), having been rolled, is separated and sieved to aerate it and this helps reduce the heat.

- The leaf is typically placed on large perforated trays to facilitate the oxidation process for between two to four hours. The leaf must be exposed to fifteen to twenty changes of humidified air per hour as it absorbs a significant quantity of oxygen. Complete oxidation is determined by many factors hence this judgement is formed by experience. Over the course of oxidation the leaf colour changes from green to yellow, to copper, then brown. Under-oxidised tea can have a metallic, green taste. Over-oxidised tea tends to be too soft and lacking in briskness and length of flavour on the finish. During oxidation polyphenols are converted into theaflavins, thence to thearubigins, the former bringing brightness, the latter strength and colour. A good balance is needed between them.

- The leaf is dried to reduce the moisture content from about 60% to around 3% over a period of fifteen to twenty minutes. This stops oxidation.

- Next, the leaf is cooled to avoid loss of flavour.

- Finally the leaf is graded and packed.

Orthodox tea manufacture is most common in India, China, Sri Lanka, Indonesia and Vietnam. Traditional skills have been revived in some growing areas to take advantage of the increasing demand for the superior flavour of orthodox teas which is increasingly demanded by more discerning customers. All our teas are made using the orthodox process. You should be able to readily appreciate the benefits of orthodox teas.

See orthodox tea in our Tea Shop. See our blog article on orthodox Ceylon teas from Sri Lanka.